13525079458

产品描述

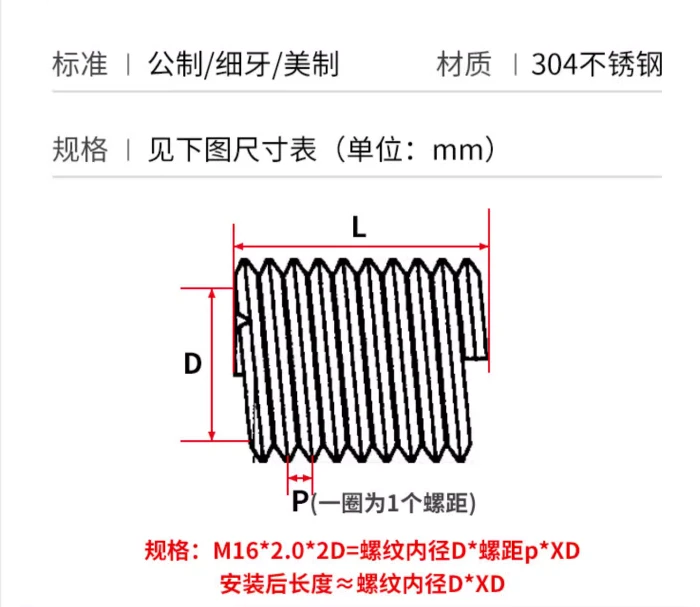

?钢丝螺套:这是一种用于加强螺丝孔强度或修复损坏螺丝孔的部件。它们通常由金属线螺旋缠绕而成,安装后可以提供更坚固的螺纹连接。

?1Cr18Ni9Ti材料:这是一种不锈钢材质,具有良好的耐腐蚀性和较高的机械性能。其中,1表示碳含量,Cr代表铬,Ni代表镍,Ti代表钛。这种材料因其优异的耐腐蚀性和抗高温氧化性,被广泛应用于化工、石油领域。

?支持定制5H 6H精度:这里的5H和6H指的是公差等级,根据ISO标准,5H和6H属于较高精度等级,分别适用于不同的配合要求。螺套的内径和外径尺寸都有严格的公差控制,以确保安装后的尺寸准确性和功能可靠性。

产品细节

表格参数

| Metric steel wire screw sleeve specification parameter table | |||||

| Thread specification d×p | k×d | Wire screw sleeve installed length L(mm) | Bit diameter d(mm) | Free external diameter Dz(mm) | Number of free spiral rings N(≈) |

| M2×0.4 | 1d | 2 | 2 | 2.6-2.8 | 2.9 |

| 1.5d | 3 | 4.7 | |||

| 2d | 4 | 6.5 | |||

| M2.5×0.45 | 1d | 2.5 | 2.6 | 3.3-3.5 | 3.5 |

| 1.5d | 3.75 | 5.9 | |||

| 2d | 5 | 8.1 | |||

| M3×0.5 | 1d | 3 | 3.1 | 3.8-4.0 | 4 |

| 1.5d | 4.5 | 6.3 | |||

| 2d | 6 | 8.7 | |||

| M4×0.7 | 1d | 4 | 4.1 | 5.15-5.35 | 3.7 |

| 1.5d | 6 | 6 | |||

| 2d | 8 | 8.4 | |||

| M5×0.8 | 1d | 5 | 5.2 | 6.35-6.6 | 4.3 |

| 1.5d | 7.5 | 6.9 | |||

| 2d | 10 | 9.7 | |||

| M6×1 | 1d | 6 | 6.2 | 7.6-7.85 | 4.2 |

| 1.5d | 9 | 7 | |||

| 2d | 12 | 9.6 | |||

| M7×1 | 1d | 7 | 7.2 | 8.65-8.9 | 5.4 |

| 1.5d | 10.5 | 8.5 | |||

| 2d | 14 | 11.6 | |||

| M8×1 | 1d | 8 | 8.2 | 9.85-10.1 | 6.1 |

| 1.5d | 12 | 9.5 | |||

| 2d | 16 | 13 | |||

| M8×1.25 | 1d | 8 | 8.3 | 9.85-10.1 | 4.7 |

| 1.5d | 12 | 7.4 | |||

| 2d | 16 | 10.6 | |||

| M10×1 | 1d | 10 | 10.2 | 12.1-12.5 | 7.6 |

| 1.5d | 15 | 12 | |||

| 2d | 20 | 16.3 | |||

| M10×1.5 | 1d | 10 | 10.3 | 12.1-12.5 | 5 |

| 1.5d | 15 | 8 | |||

| 2d | 20 | 11.2 | |||

| M12×1.5 | 1d | 12 | 12.4 | 14.4-14.8 | 6.2 |

| 1.5d | 18 | 9.8 | |||

| 2d | 24 | 13.5 | |||

| M12×1.75 | 1d | 12 | 12.4 | 14.4-14.8 | 5.2 |

| 1.5d | 18 | 8.4 | |||

| 2d | 24 | 11.7 | |||

| M14×1.5 | 1d | 14 | 14.4 | 17.2-17.7 | 7 |

| 1.5d | 21 | 11.2 | |||

| 2d | 28 | 15.3 | |||

| M16×1.5 | 1d | 16 | 1** | 19.4-19.9 | 8.3 |

| 1.5d | 24 | 13 | |||

| 2d | 32 | 17.7 | |||

| M16×2 | 1d | 16 | 16.5 | 19.4-19.9 | 6 |

| 1.5d | 24 | 9.7 | |||

| 2d | 32 | 13.3 | |||

| M18×1.5 | 0.5d | 9 | 18.4 | 21.5-22 | 4.4 |

| 1.0d | 18 | 9.5 | |||

| 1.5d | 27 | 15 | |||

| M20×1.5 | 0.75d | 15 | 20.4 | 23.7-24.2 | 8 |

| 1d | 20 | 10.7 | |||

| 1.5d | 30 | 16.7 | |||

| M20×2.5 | 1d | 20 | 20.5 | 23.7-24.2 | 6.3 |

| 1.5d | 30 | 10 | |||

| 2d | 40 | 13.7 | |||

| M22×1.5 | 0.75d | 16.5 | 22.4 | 26.3-26.8 | 8.6 |

| 1d | 22 | 11.7 | |||

| 1.5d | 33 | 18 | |||

| M24×1.5 | 0.75d | 18 | 24.4 | 28.6-29.1 | 9.5 |

| 1d | 24 | 13 | |||

| 1.5d | 36 | 19.8 | |||

| M24×3 | 1d | 24 | 24.6 | 28.6-29.1 | 6.3 |

| 1.5d | 36 | 10 | |||

| 2d | 48 | 14 | |||

| M26×1.5 | 0.5d | 13 | 2** | 30.5-31 | 6.7 |

| 0.75d | 19.5 | 10.7 | |||

| 1d | 26 | 14.6 | |||

| M27×1.5 | 0.5d | 13.5 | 27.4 | 32.2-32.7 | 6.7 |

| 0.75d | 20.3 | 10.7 | |||

| 1d | 27 | 14.6 | |||

| M27×2 | 0.5d | 13.5 | 27.5 | 32.2-32.7 | 6.7 |

| 0.75d | 20.3 | 10.7 | |||

| 1d | 27 | 14.6 | |||

| M30×1..5 | 0.5d | 15 | 30.4 | 35.2-35.7 | 7.8 |

| 0.75d | 22.5 | 12.2 | |||

| 1d | 30 | 16.5 | |||

| M30×3.5 | 1d | 30 | 30.7 | 35.2-35.7 | 7 |

| 1.5d | 45 | 11 | |||

| 2d | 60 | 14.9 | |||

| M33×1.5 | 0.5d | 16.6 | 33.4 | 38.3-38.8 | 9.1 |

| 0.75d | 24.5 | 13.7 | |||

| 1d | 33 | 18.3 | |||

| M39×2 | 0.5d | 19.5 | 39.5 | 45.1-45.6 | 7.9 |

| 0.75d | 29.25 | 12.2 | |||

| 1d | 39 | 16.6 | |||

| M60×4 | 0.5d | 32 | 64.9 | 65-66 | 7.3 |

| 1d | 64 | 15.6 | |||

扫一扫关注我们